Introduction to Robots-as-a-Service

The business model for buying and selling industrial equipment is rapidly evolving. The convergence of cloud-based solutions for IT infrastructure and the success of Software-as-a-Service (SaaS) enterprise software licensing is now influencing how Autonomous Mobile Robot companies are selling their solutions. Autonomous Mobile Robot companies such as Locus Robotics, inVia Robotics, Savioke (now Relay Robotics), Cobalt Robotics and Knightscope have demonstrated success in delivering solutions with business models which enable customers to pay-as-they-go in a subscription or metric-based financing model. Let’s look at how you should evaluate a Robots-as-a-Service (RaaS) offering from a potential robot supplier.

Executive summary

This article introduces the business model for deploying robotic-based solutions as a service or as a subscription model. For the buyer of Autonomous Mobile Robot (AMR) solutions, this white paper will outline how the concept of subscription-based pricing and service delivery is different from the classic capital equipment sales and support model. This will prepare you to conduct an educated proposal process and acquire the right solution for your automation needs.

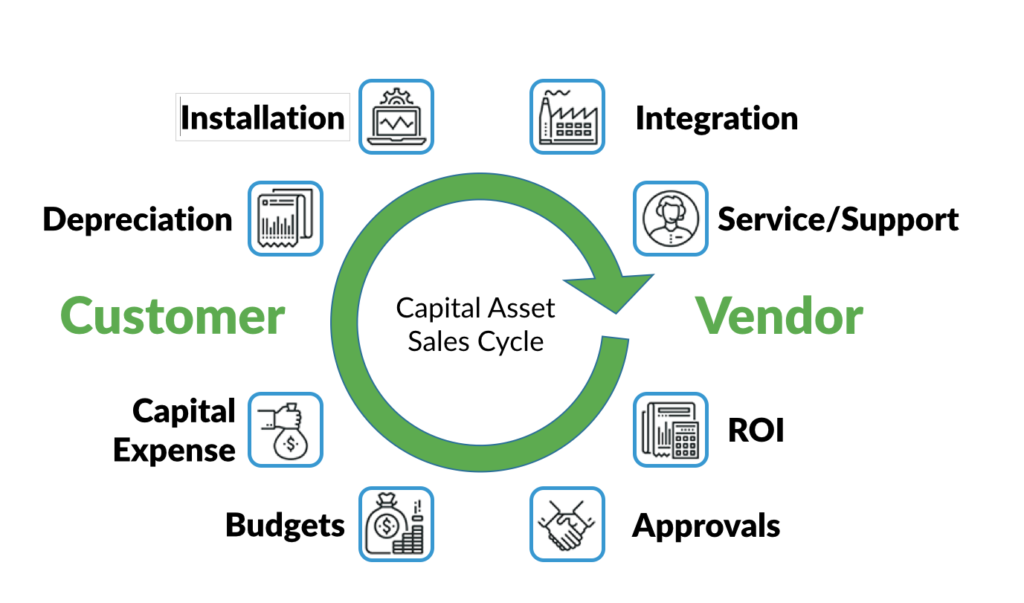

For more than 30 years, the robotics market has operated on the “classic” capital equipment product design and sales business model. Under this sales strategy, new products are developed to meet a market need and then marketed and sold to target customers as a capital asset purchase.

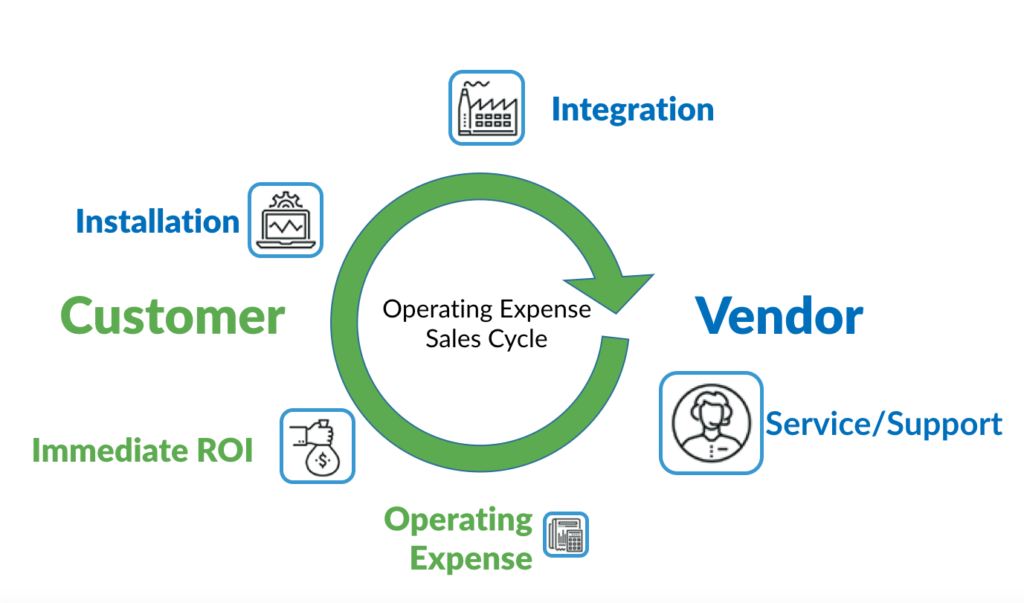

As a customer, you own the equipment, depreciate it as a capital asset over its working life and are responsible for the maintenance and repair of the equipment over its lifetime. At the end of the product life, you are responsible for the disposal of obsolete equipment. RaaS changes all of that. In a Robots-as-a-Service contract, you only pay for what you consume and all of the deployment, integration, support and equipment maintenance costs are included in the service level contract.

Like any subscription business model, you will get better rates by signing a longer-term contract with the RaaS vendor.

Are you a robot manufacturer?

This article is focused on the RaaS story from the perspective of the automation buyer, and you should finish reading it. However, we’ve produced a separate article that helps robotic automation vendors design, build and optimize a RaaS-based automation business.

The capital asset approval cycle

The annual nature of the capital asset purchasing cycle imposes a purchasing cycle which can vary anywhere from 3 to 18 months. Depending upon your organization, you might be subject to an annual budgeting process in which you need to submit capital budget requests months ahead of when you anticipate you might need the equipment in your facility. Building the business case for expensive, fixed asset, capital equipment often requires many layers of management approval.

A subscription model such as Robots-as-a-Service changes the entire purchasing process, often simplifying and shortening it. With a RaaS contract, you can pay for the automation out of your operating budget, a budget that you likely control without having to seek a capital approval within your organization.

Finally, to manage the pace of innovation and hypergrowth within some business segments (such as ecommerce), you may be faced with short planning horizons to predict automation needs. It can be impossible to accurately predict your warehouse throughput requirements twelve to eighteen months down the road. The promise of RaaS is that it provides an opportunity to better utilize your capital while shortening the window required to acquire and deploy an automation solution that meets your needs.

Key Takeaway: The buying process for RaaS is often shortened because the budget is controlled at the operational manager/director level.

Pay for what you consume

A RaaS model allows you to scale up and scale down your consumption as your automation needs change. You are purchasing a complete end-to-end service rather than a good, in the same way that you might sell your lawn mower and outsource your lawn care: ordering twice-weekly service during peak season and canceling the service in the dead of winter. Not every automation application is a good fit for RaaS. Target applications for Robots-as-a-Service will have similar hallmarks to the lawn care example. Look for applications where you can leverage additional robot usage during peak periods and idle or halt service during slow periods, with a variable rate of payment based on consumption. Robots-as-a-Service is like hiring a temp agency for your robotic workforce.

Key Takeaway: With RaaS, you can easily get out of the relationship if the solution isn’t working for your business. This adds additional incentive to your vendor to go the extra mile to successs

Register now for the 2024 Robotics Summit.

Register now for the 2024 Robotics Summit.

RaaS advantages for the buyer:

Robots as a Service is emerging as a dominant method for financing automation projects. Here’s a list of the Pros and Cons for RaaS:

Pros

- Simplified return on investment (ROI) criteria.

- Elastic consumption (pay for what you use, and scale to meet production peaks/valleys).

- Free software upgrades.

- Higher quality equipment.

- More intimate vendor support.

- Comparable consumption rates to manual labor.

Cons

- Capital investment and depreciation is not an option.

- Limited customization of vehicle and/or payload.

- You never own the equipment.

Conclusion:

For the right automation applications, Robots as a Service can be the simplest and fastest way to procure and deploy an autonomous mobile robot.

A more intimate vendor relationship

As you evaluate the viability of RaaS for your business, the first step is to understand the organizational changes that a RaaS business model imposes on your vendor. Some vendors are committed to a 100% RaaS business model, while others are offering RaaS as just one of the ways in which you can acquire their solution. Let’s look at some elements which are different in a RaaS vendor relationship over a CapEx purchase of capital equipment.

Vendor owned equipment

First, the vendor will continue to own the equipment. Therefore, the vendor will have the expectation and functionality to remotely monitor the solution in production. This will require remote access to the equipment through your corporate network. The benefit to your organization is that you don’t need to train and maintain in-house robot experts. The vendor will also carry the burden of 24/7 support. If a robot breaks down, the vendor will likely know before you do, through the remote monitoring system. The vendor will likely be able to remotely troubleshoot the equipment and schedule onsite repair, often without any interaction on your part.

Key Takeaway: If the equipment breaks, you don’t have to fix it. Often the vendor will simply ship a replacement machine, or enable an additional machine stored on site.

Updates included

Second, because the vendor owns the equipment, they will be able to update it as needed to keep it in prime operational condition. In fact, the vendor has all of the right incentives to design, build and maintain the best software and hardware, since they are designing for long-term operation and supportability. The vendor might even redeploy robotic equipment across multiple customers, as the need arises. This financial incentive helps the vendor to optimize their investment. Vendors who offer their solution only in a RaaS model will likely have higher quality equipment and service than a vendor who is reactively offering RaaS as an option to a capital equipment purchase.

Key Takeaway: Your vendor is incented to improve the software functionality over time. The more efficient it operates, the fewer machines are required to solve your needs.

Leasing is NOT Robots-as-a-Service!

A simple solution to the financing issue might appear to be the use of a leasing agent as a financing intermediary with the customer. However, a leasing contract alone is not a RaaS solution and you should be wary of a supplier attempting to sell a leasing option disguised as RaaS solution. While leveraging a leasing contract to acquire a piece of capital equipment may be an option to consider, don’t be fooled that it is a RaaS business relationship.

Key Takeaway: A leasing contract may be one way to fund the equipment, but it doesn’t tie your vendor to the net positive outcome like a RaaS model does.

The three requirements of a RaaS solution

There are specific application requirements that must exist for a RaaS-based solution to be viable. Let’s look at a few of these.

1. The automation problem must be scalable

Your problem must be measurable by some key performance indicator (KPI). As the saying goes, “if you can’t measure it, you can’t manage it”. There must be some immutable way to measure the KPI’s and consumption rate for the RaaS solution to be viable. This KPI measurement must in turn be effectively reported on and invoiced by the supplier. For example, a simple measure would be hours of operation. In this case, you would pay for every hour that the AMR is operating (i.e. not turned off or charging). Another measure might be “per pick”. In this example, you might pay for every package moved through the facility.

2. Chargeable to an Operating Expense

The second requirement of a RaaS solution is that the operation in question must be funded by an operating expense (OpEx) since the hardware won’t be capitalized. OpEx dollars are typically discretionary for the purchasing manager, without the need to seek high-level approval. Executive approvals can be a deal killer in a capital expenditure buying process. So, if you have OpEx budget to spend on automation, RaaS may be the perfect solution.

3. Guaranteed throughput

Two of the key metrics that every production manager cares about are: production throughput and production quality. Automation tools leveraged in the manufacturing process are measured by this requirement. Production spikes are inevitable, and enabling your production team to smooth production spikes is advantageous to your production metrics. In service robot applications, the solution is more task or demand driven in its application as opposed to the process-centric needs of manufacturing. In this situation, the robot may spend time idle, as it waits for the next request or job to come in. Likewise, in a service application, there are likely to be periods of overconsumption or periods in which there are more tasks to do, than robots to do it. RaaS can help solve consumption bottlenecks in the application, as you’ll be able to arrange for additional capacity as production demands increase. InVia Robotics is one RaaS vendor who offers customers the ability to scale up throughput by delivering additional robots to your facility during peak periods, for ecommerce vendors this might be during the holiday season.

Five things to ask a vendor when considering a RaaS solution:

- Do you offer remote monitoring of the solution in production? If so, what are your IT security considerations and certifications?

- How do you measure the throughput of the RaaS solution, and how will I be billed for that service? Can I see my consumption report on a daily basis? Is there a minimal charge for usage each month/quarter?

- Can I scale up or scale down the number of autonomous mobile robots which are deployed in my facility during the contract?

- Is there an upfront charge for integration of the solution in my facility?

- Can I customize the payload of the autonomous mobile robot for my unique needs?