SICK announces a new linear speed and distance measuring sensor with the new SPEETEC® sensor. The SPEETEC® is capable of speed and length measurement of objects moving in a linear path and it includes technology that measures directly from a material’s surface. The non-contact sensor is able to measure a wide range of web and continuous materials, as well as blanks with an accuracy of just 4 µm.

Useful For Direct Surface Measurement

The SPEETEC® is designed for sensitive, soft, or smooth surfaces. It is specifically useful in applications from factory or logistics automation where non-contact measurement is required. The sensor can measure the length, speed, and position of continuous webs and blanks.

The SPEETEC® offers a new way to measure without slip, measuring elements or marking, and wear and tear on tactile sensor elements. Materials that cause wear, adhesion, or abrasion damage to measurement solutions such as measuring wheel encoders, impairing their function, can be measured by the SPEETEC® with a high degree of process reliability and availability.

How The SICK SPEETEC Works

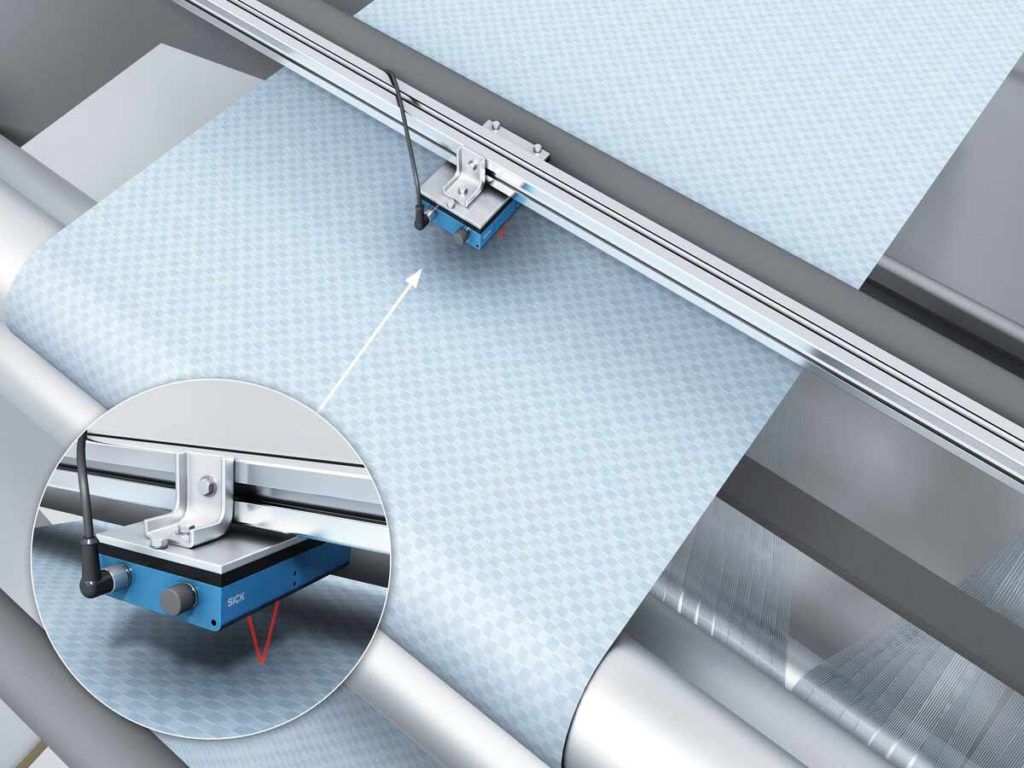

The non-contact measurement is performed with a laser Doppler process at speeds of up to 10 m/s. Two transmitters emit laser light – one in the direction of movement of the material, the other in the opposite direction. Since the transmitters work independently, possible mounting tolerances and surface fluctuations (i.e., with wavy surfaces) can be balanced out.

The SICK Speetec is use for measuring distance and speeds on variable materials. (Image courtesy of SICK Sensors)

All measurements are done with high precision. At a resolution of four micrometers, the accuracy relating to the object length of a meter is one millimeter. The repeatability in this case is specified with a half a millimeter. Measured values are output via the TTL or HTL interfaces common in the encoder world, making integration easy.

With the SPEETEC®, length, speed and position can also be detected in linear movements when switching between forward and backward motions. In addition, acceleration measurement in applications with high motion dynamics is possible since, with the SPEETEC®, only three milliseconds pass between the start of the movement and the output of measured values.

Applications In Mobile Robots?

The new sensor measures only in single dimension, which may limit its application for mobile robotic navigation, however, the ability to measure distance to any surface, without the need for specialized reflectors, opens the door to new application areas. If you have a need for enhance accuracy in a single dimension, then this new sensor may be the answer.

For more information, and complete technical specs, check out the SICK SPEETEC website.

Tell Us What You Think!

You must be logged in to post a comment.